The companies of the STAUFF Group and their authorised system partners offer original equipment manufacturers in the fields of mobile and industrial hydraulics the following services with regards to the production and further processing of ready-to-install hydraulic pipes and tubes:

- Automatically controlled and monitored bending of seamless precision tubes made of carbon steel (Zistaplex®, Zista® Seal, zinc plated, phosphated, untreated), stainless steel, copper and various special materials in a large variety a common metric tube diameters and wall thicknesses and lengths up to 6 metre

- Automatically controlled and monitored assembly of cutting rings and union nuts

- Tube end forming with STAUFF Form and other common systems

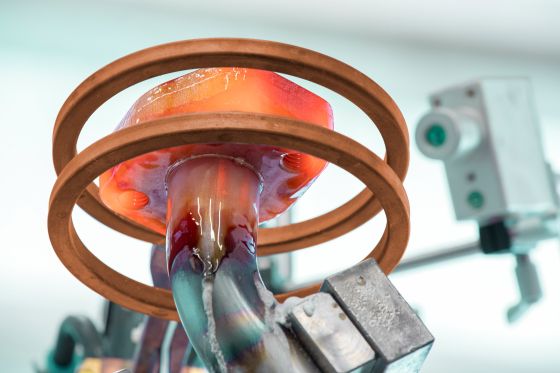

- Inductive soldering, brazing as well as WIG, MIG and MAG welding for non-positive connections

- Testing according to standard or customer’s specification

- Cleaning to achieve specific cleanliness levels and specifications

- Sealing and protecting the tube ends and other connections

Surface Protection from STAUFF

- Zista® Seal provides additional sealing for improved corrosion protection even after forming

- Zistaplex® describes the solution for the most demanding applications with even higher corrosion protection through an additional organic top layer.

Global Center of Excellence

With its headquarters located in Sheffield (United Kingdom), STAUFF UK Ltd. forms the Global Center of Excellence for tube manipulation within the STAUFF Group. For almost 30 years, the design of complex pipework systems and the manufacturing and processing of tubes in accordance with customer requirements has been part of the daily business of the specialists on site.