What is a Solar Tracking System?

A solar tracker is a system that positions a solar panel, made of various materials like photovoltaic panels, reflectors or lenses, towards the sun. Solar tracking systems allow the panels to maximize the amount of sunlight they can capture. This helps increase efficiency by continually repositioning the panel to angle it in the sun's direct path. Solar tracking systems are pivotal to the generation of solar power. As the system continually adjusts the position of the panels to face the sun at the most optimal angle, solar panels can capture significantly more energy than stationary panels.

How Do Solar Tracking Systems Work?

Solar tracking systems have a variety of parts that work together to help the panel move as the sun changes position. A tracker mount holds the solar panel in certain positions, fostering stability and security. The driver will control the rotation of the motor shaft, which moves the tracking system.

Sensors will measure sunlight and send signals to find the best position for optimal exposure. The motor or power pack creates fluid pressure energy, and this energy is transported to the hydraulic actuators. Hydraulic actuators, usually cylinders, change this fluid energy into mechanical energy, and this energy creates motion.

What are Power Packs?

A hydraulic system in a solar tracking system is critical to the production of solar energy. The fluid energy created is sent to the hydraulic actuators, which converts the fluid energy into mechanical energy that puts the system into motion. These power packs tend to be small and compact in design. When designing a power pack of this nature it is important that the parts involved offer durability and functionality while also being small enough to fit in such a compact space.

What Requirements are Important to Power Pack Manufacturers and Installers?

When choosing the right components for building power packs and for installing the hydraulic system into the solar tracking system, there are certain requirements that must be met to achieve optimal system performance.

- Because of the design of solar tracking systems, power packs and hydraulic systems are small and compact. The components used must also be small and lightweight making it easy to install and ensure a secure and leak-free connection.

- Solar panels face various environmental factors on a continuous basis. Exposure to UV light, temperature fluctuations, corrosion, and precipitation are just a few variables that can potentially compromise the functionality of components. All components must be reliable and crafted from materials that foster durability and strength.

- Solar panels typically occupy remote locations, reliable components that require minimal maintenance are critical. The hydraulic system in the solar tracker is small and hard to reach, making maintenance complicated and time-consuming.

- When maintenance or component replacement is needed, using standardized parts worldwide helps lower costs and improve system performance.

What Components Do People Typically Use in Hydraulic Power Pack Manufacturing?

Because the reservoir contains fluid, it is imperative that power packs include level gauges. Level gauges detect and indicate the level of the hydraulic fluid in the reservoir in real time. STAUFF offers level gauges in a compact design, Type SNKK, which is specifically designed to be installed for easy visibility in compact spaces. Due to power packs being manufactured in different versatile ways Blank Plugs for Tube Ends are often integrated into power packs to ensure cleanliness and a secure seal on the tank.

Breathers are critical components in fluid systems as proper ventilation and hygiene of the fluid allow for efficient system performance. Filler breathers are one type of breather that acts as a fill location where fluid can be added to or be taken out of the hydraulic tank, as well as acting as a tank breathing device allowing air to flow in and out.

STAUFF Mini Plastic Filler Breathers are threaded and compact allowing the system to breathe and be easily accessible at all times, while offering protection from contamination. Additionally, particle and desiccant breathers prevent moisture and contamination from entering the fluid tank. STAUFF Particle and Desiccant Breathers of TYPE SDBL, are a compact design that ensure proper cleanliness of the fluid in the reservoir and are equipped with check valves.

What Components Do People Typically Use in Hydraulic Power Pack Installation?

Builders and installers are responsible for assembling the full hydraulic system on-site. This includes connecting the hydraulic power pack to the hydraulic actuators. These connecting parts vary from the components used to build a power pack. Connecting components help ensure there is a leak-free transfer of fluid from the power pack to the actuator during the process of energy conversion.

Tube assemblies and hose assemblies are the main lines of connection between the two parts of the system. The space and the system will determine whether tubes or hoses will be used. The STAUFF Flex Ultimate High-Pressure Hose is a strong hose for fluid systems and offers great durability. It can withstand temperatures up to 275°F (135°C).

Connecting tubes and hoses to the systems themselves requires fittings that are cost effective and reliable. The STAUFF Connect Metric Fittings offer standardization across the globe with a wide range of sizes and types. They come equipped with a Zinc/Nickel Surface Coating that offers 1200 hours of corrosion resistance. These components, when installed properly, guarantee a leak-free seal, requiring low maintenance.

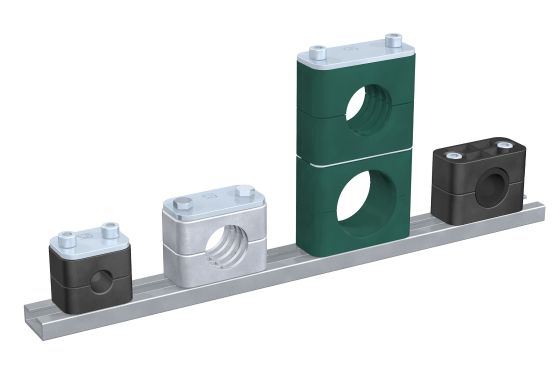

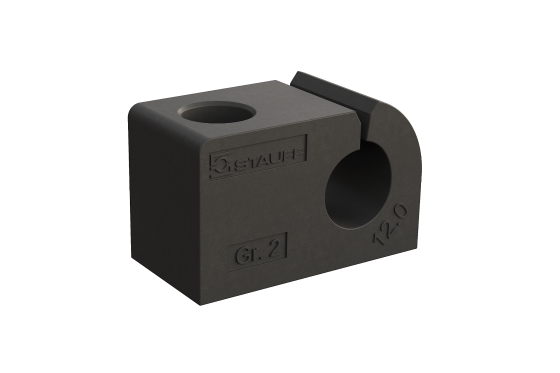

Clamps for hoses and tubes that are designed for compact spaces and made of durable and reliable materials ensure that tubes and hoses are securely assembled and organized. STAUFF DIN Clamps made from polyamide PA resist UV light making them durable for solar applications. Other STAUFF DIN Clamps made from aluminum provide extra strength, ensuring they can withstand any environmental conditions without damage. STAUFF LBBU clamps are strong, lightweight, and compact, making them ideal for applications where space is limited and difficult to access.

Image 1 Courtesy of Mechatron Solar: Mechatron Solar Gains UL3703 Dual-Axis Tracker Certification

Image 2 Courtesy of Mechatron Solar: Solar Tracking Optimizes the Yield of Photovoltaic Systems By Almost 50 Percent

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog