The STAUFF Zinc/Nickel Coating

In hydraulic technology, the demands for corrosion protection and durability are higher than ever. The STAUFF zinc/nickel coating sets new standards. With over 1,200 hours of resistance to red rust in the salt spray test chamber, it not only exceeds market standards but also offers an aesthetically pleasing and sustainable solution for several product groups in the extensive STAUFF range. This article demonstrates how we ensure the quality of this coating with state-of-the-art technology and the benefits our customers derive from it.

Quality Assurance Through Innovative Measurement Technologies

To maintain the quality of the STAUFF zinc/nickel coating at a consistently high level, STAUFF has recently invested in another state-of-the-art measuring device: the FISCHERSCOPE® X-RAY XDLM®. This new device enables more precise and efficient inspections than ever before and takes our quality control to the next level. Key advantages of this technology include:

X-ray-based measurement: Checks zinc/nickel layers as well as other electroplated coatings.

Patented DCM method: Stepless adjustment of the measuring distance for optimal results, even on uneven components.

Largest measuring window on the market: Allows quick and efficient analyses.

Automated series testing: Perfect for the inspection of mass-produced parts.

With the introduction of this technology, STAUFF can work even better towards consistently high quality. Our customers benefit from increased reliability and the assurance that all products undergo rigorous testing. The new device was commissioned at the Meinerzhagen site and is now an integral part of the testing of hose fittings, tube connectors, and couplings.

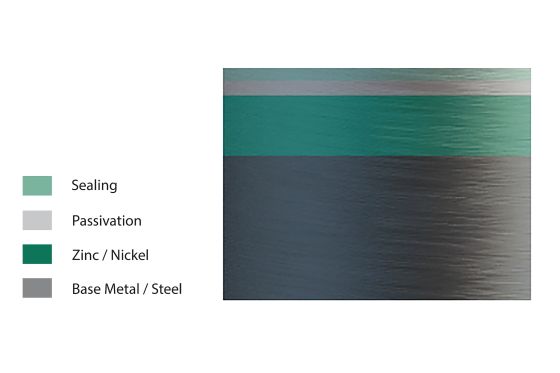

What Makes the STAUFF Zinc/Nickel Coating Special?

The STAUFF zinc/nickel surface offers a highly effective corrosion protection, proven through numerous tests in the salt spray chamber (DIN EN ISO 9227). Here are some of its outstanding features:

Corrosion protection beyond standards: More than 1,200 hours of resistance to red rust, with minimal occurrence of white rust.

Free from hexavalent chromium (CrVI): Environmentally friendly and compliant with current regulations such as REACH, RoHS, and ELV.

High-quality appearance: Bright, slightly glossy surface resembling stainless steel.

Versatility: Suitable for a variety of products such as STAUFF clamps, tube connectors, valves, and test couplings.

Enhanced wear resistance: High ductility reduces wear even under demanding conditions.

These properties make the STAUFF zinc/nickel coating the ideal choice for applications where durability and reliability are crucial.

State-of-the-Art Electroplating Processes

The refinement of STAUFF products takes place in high-performance partner electroplating facilities located near our production and logistics sites in Germany. These short distances ensure flexibility and efficiency. Two processes are in focus:

Barrel Electroplating

Efficiency: Ideal for smaller, less sensitive components that can be processed as bulk goods.

Automation: All steps, from pre-treatment to drying, are centrally controlled.

Rack Electroplating

Precision: For more sensitive components that cannot be processed as bulk goods.

Custom adaptation: Product-specific hanging devices ensure optimal coating.

Both processes are monitored by state-of-the-art technology and guarantee the highest quality.

Sustainability and Compliance

The STAUFF zinc/nickel coating for hydraulic line components not only meets all relevant legal requirements but also sets standards for sustainability in coating:

Environmentally friendly: Free from CrVI and compliant with REACH, RoHS, and ELV.

Durable: Reduced material consumption through increased component longevity.

Resource-efficient: Highly efficient processes minimize waste and emissions.

These features make the coating a responsible choice for the industry.

FAQs

What is STAUFF Zink/Nickel coating?

Which products are available with this coating?

It is used as standard for STAUFF clamps, tube fittings, valves, test couplings and many other components.

How is the quality of the coating checked?

Quality is ensured by layer thickness measurements, corrosion tests and other modern testing methods.

Is the coating environmentally friendly?

Yes, it is free of hexavalent chromium and complies with the REACH, RoHS and ELV directives.

What are the advantages of the coating?

Our STAUFF Zink/Nickel coating offers longer-lasting corrosion protection compared to similar coatings from competitors. This means that components with a Zink/Nickel coating also offer an alternative to stainless steel components in many applications, which are usually more expensive.

Newsletter

Subscribe to the newsletter now and never miss a new post again.