Production exchange filter elements

Replacement filter elements for hydraulic and lubricating oil in original equipment quality from STAUFF

The STAUFF Blog provides you with an exclusive look behind the scenes. Shown here for the first time in this form are the relevant work steps in the STAUFF manufacturing plant in Werdohl-Ehrenfeld (Germany) for the production of a typical replacement filter element for hydraulic and lubricating oil in OEM quality.

Selection of the required filter materials

Qualified and experienced employees select the appropriate filter materials according to the order from the extensive stock, which is always kept in stock close to production at STAUFF.

STAUFF mainly uses media such as inogranic glass fibre, filter paper, stainless steel fibre, stainless steel wire mesh and polyester fibre with a micron rating between 3 µm and 250 µm.

Cutting of filter material

The filter materials are cut to the required dimensions by machine and with a high degree of precision. Variable widths between 20 and 1200 mm are technically feasible with the current machinery.

Combining filter materials

The automated combination of up to seven different filter materials increases the longevity and later performance of STAUFF filter elements in the separation of particles in the oil.

A typical hydraulic filter element from STAUFF consists of several layers of support mesh and support paper as well as one layer each of pre-filter and main filter material.

Production of filter pleats

The so-called filter pleats with a variable height between 4,5 mm and 50 mm are manufactured in the filter pleating process. Automated star-pleating maximises the total filter area, which enables increases filtration performance in the smallest space.

As a quality manufacturer, STAUFF manufactures all the filter pleats required for the production of replacement filter elements in-house with its own machinery.

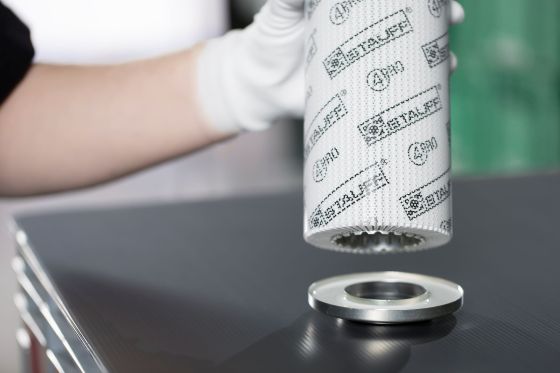

Manufacturing of the protective cover sleeves

In this step, perforated plastic foil is cut to size and ultrasonically welded into the shape of a sleeve, which is later slid over the assembly of support tube and filter pleats and glued to the end caps.

In selected series, the protective cover provides additional protection of the replacement filter element against larger particles and ensures a more even distribution of the volume flow.

Quality control

Quality control takes place at several points throughout the entire production and assembly process.

Quality control is an important part of quality assurance at STAUFF. It involves the systematic monitoring of all factors that can influence the consistently high quality of replacement filter elements in production and assembly.

Provision of the other components

Other necessary components, such as support tubes, end caps and sealings, are stocked close to production so that even urgent customer requirements can be implemented quickly.

Automated and therefore highly efficient storage lift systems are used for the storage and provision of light or small-volume components.

Manufacturing of the assembly of support tube and filter pleats

The combination of the mostly internal support tube made of steel or stainless steel with the correctly sized filter pleats forms the centrepiece of the replacement filter element.

The filter pleat is placed around the perforated support tube. Both ends are then glued together and pressed tightly together using a stainless steel profile.

Assembly of the first end cap

The previously manufactured assembly of support tube and filter pleat is inserted into the first of the two end caps, which was previously filled with special adhesive.

In the course of this, the sleeves of protective cover are also mounted, if necessary.

Among other things, the protective cover prevents damage to the sensitive filter pleats during transport, storage and element replacement.

Marking of the end cap

The end cap is usually laser-marked according to STAUFF standards (i.e. with STAUFF logo, STAUFF material number, STAUFF order designation and coded information on the exact time of production) or according to specific customer requirements. The advantages of this process are obvious: laser marking offers a high degree of flexibility, is equally suitable for end caps made of metal and plastic and is carried out quickly, without contact and without drying times. The result: a precise, high-contrast, abrasion-resistant and thus highly visible and durable marking of the hydraulic filter element.

Assembly of the second end cap

The previously manufactured assembly of support tube, filter pleat and first end cap is inserted into the second of the two end caps, which was previously laser-marked and then filled with special adhesive as well.

Assembly of the sealing(s) and final visual inspection

With the assembly of sealing(s), e.g. made of Perbunan® (NBR), Viton® (FPM/FKM) or ethylene propylene diene monomer rubber (EPDM), to the end caps, depending on the design of the filter element, the production is formally completed.

Experienced and qualified specialists carry out a final visual inspection and check all STAUFF replacement filter elements for contamination or damage.

Shrink-wrapping in foil

To protect against dust and other external contaminants that could otherwise enter the hydraulic or lubricating oil system via contaminated filter elements and cause damage there, STAUFF replacement filter elements are shrink-wrapped in transparent foil as standard.

This step takes place immediately after the final visual inspection of the filter element.

Packaging and labelling

Before being palletised and shipped to the automated STAUFF logistics centre, STAUFF replacement filter elements are packed in precisely fitting cardboard boxes.

Green STAUFF labelled cardboard boxes are typically used, which results in a high recognition value of STAUFF quality filters among customers and users.

Unless explicitly requested otherwise, the STAUFF logo and the STAUFF material number as well as the STAUFF order designation can be found on the label.

Replacement filter elements "made in Germany

Flexible production and assembly lines in the factory in Germany as well as extensive stocks in the automated logistics centre guarantee unrivalled fast delivery times.

STAUFF subsidiaries and a tight network of system and trade partners ensure the availability of STAUFF replacement filter elements in all industrial regions worldwide.

Rate and Comment

Rate posts in the STAUFF blog with just one click or leave feedback and suggestions as a comment – without registration

The editorial team of the STAUFF blog appreciates feedback and suggestions. Accordingly, readers can now not only rate all posts, but also leave comments as guests without prior registration.

And it's that simple:

- Read or view the article.

- Scroll to the bottom of the page.

- Rate the post with just one click.

- Enter a comment.

- Submit your comment as a guest (only your name is required) or create a user account.

- After the comment has been reviewed and approved by the editorial team, it will be published online.

What do you think of this new feature?

Please share your opinion with us now using the rating and comments function!

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog